Maximum Impact: Professor-student Team Uncovers Engineering Applications in Bighorn Sheep Horns

December 16, 2020

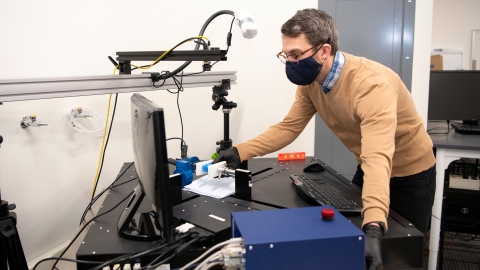

Professor Benjamin Wheatley, mechanical engineering, subjected models of a bighorn sheep's inner horn structures to stress tests in his latest study. Photo by Emily Paine, Communications

It's one of the most violent spectacles in the natural world: Two bighorn sheep square off at 10 paces, rear up on their hind legs and rush, dropping their heads at the last moment to crash their horns together with maximum impact. And then they do it again, sometimes for hours on end, before walking away apparently no worse for the wear.

Bucknell Professor Benjamin Wheatley, mechanical engineering, occasionally witnessed these clashes in Estes Park, Colo., while he was studying for his doctorate at nearby Colorado State University. It sparked his curiosity. If such similarly violent head-to-head collisions result in concussions and even life-threatening injuries for football players, he wondered, how can these sheep avoid such trauma? What might we learn by understanding exactly how their horns absorb and deflect impact to protect their brains?

Together with first-year engineering student Jake Schaefer '24 and collaborators at institutions including Colorado State and the University of Massachusetts Amherst, Wheatley is now at work answering that question. The team is exploring applications that could yield better protection for everyone from athletes to long-term hospital patients to drivers in their cars.

In November, the researchers published a significant step toward that goal: a paper in the open-access journal Scientific Reports that examines how the interior structure of a sheep's horn might be mimicked to create better shock-absorbing materials to protect human bodies.

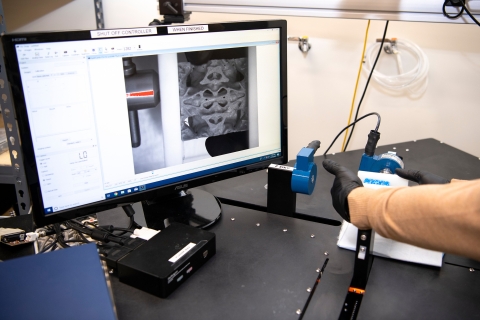

The study used CT scans from five sheep skulls provided by Colorado's Department of Natural Resources. Photo by Emily Paine, Communications

According to Wheatley, sheep's horns have two structures that enable them to absorb impact: a hard interior bone that stores energy and the softer curved structure that's visible on the outside. In the instant after the clash, he explains, "instead of the energy going toward the brain, it goes into this bony structure and gets stored there. But over time that energy has to go somewhere, and what we hypothesize is that the horn vibrates to do that."

For the latest study, Wheatley and his collaborators examined the latticework of supporting struts and gaps inside the interior bones, called "velar bone structures," to see if it might be mimicked to create better shock-absorbing soles in athletic shoes.

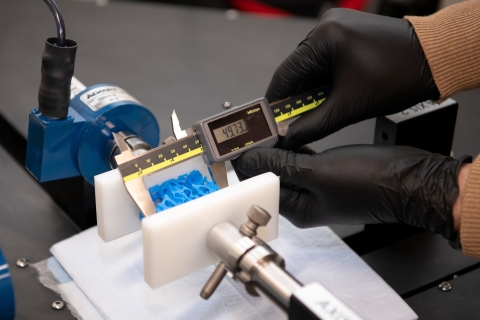

They began with the real thing: Colorado's Department of Natural Resources provided five skulls from sheep that were killed in motor-vehicle accidents and frozen shortly after death. The skulls were imaged using a CT scanner, and Wheatley and collaborators set to work optimizing their support structures with computer design and analysis software. The better-than-natural structures were then remade with advanced 3D printing, giving the researchers models they could test with real-world equipment.

Their early findings were mixed: It turns out that shoe companies have gotten pretty good at designing cushions for footwear, and the horn structures didn't prove as flexible as sneaker soles in absorbing sudden impacts, although they stored energy just as well. It appeared that the ability of the rest of the horn to vibrate plays a bigger role in dissipating the force of the blow.

That's where Schaefer comes in. From his first days on campus this fall, the mechanical engineering major from Lancaster, Pa., has been diving into the ins, outs and arounds of horns, with an eye toward discovering how their properties might be mimicked to create other protective materials.

"For the first couple weeks, I had to do a lot of reading to understand ram horns and the context, but also I spent some time learning how to 3D print," Schaefer says. "I was able to print a ram skull and a bison skull, a musk ox skull — learning to model the different horns and getting some skills that will be useful over the time I'll be spending on this project."

It's the perfect project for Schaefer, who chose to major in engineering to uncover how his innate fascination with math and physics plays out in the real world.

Wheatley improved the geometry of the sheep's inner horns to create 3D printed models used in testing. Photo by Emily Paine, Communications

"Thousands of years of evolution have led to these structures being this optimized," he says. "These animals have developed this stuff for a reason, to withstand impacts, and it's really interesting to think about the possible applications we might develop from that."

Schaefer was thrilled to begin exploring that interest from his first semester, an opportunity he gained through his Presidential Fellowship, a scholarship that allows students to partner with faculty on projects throughout their four years at Bucknell.

He'll continue his work next semester, when he plans to bring real-world physics into the equation by constructing a drop tower to test impacts (using high-speed photography and other tools) of different shapes and configurations of horns. Manipulating different models he's already created in the computer-aided design program Fusion 360, Schaefer asks, what happens when you flip the horns upside down or sideways, or stretch or compress their shape? What if there were four or 16 of horns instead of just two?

The data he uncovers will play a major role in the next phase of the research, which Wheatley says shows promise for a wide array of applications.

"It's anything from better protection in automotive impacts to vibration dampening for any number of things," Wheatley says. "There might be horns on a mountain bike to reduce vibrations, for instance. We can leverage these structures in any system that might be uncomfortable or dangerous."