Caiden Covell '25, Mechanical Engineering

December 1, 2023

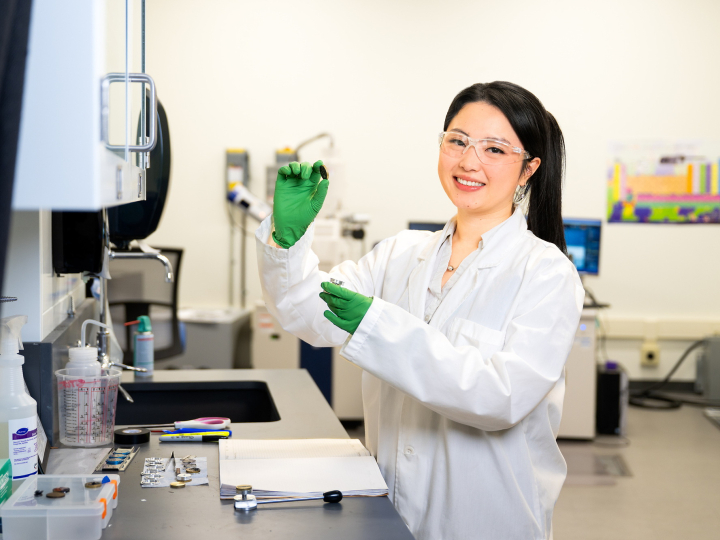

As part of his Presidential Fellowship, Caiden Covell '25 is designing and building his own soft robot. Photo by Emily Paine, Communications

Bucknell had the right kind of options for me.

Engineering is the only career path that Caiden Covell '25 had ever considered. "It's important to me to find the work that I'm doing to be both engaging and meaningful," he says. "Engineering provides that."

In his first two years at Bucknell, Covell has already had hands-on opportunities to explore the field. As part of his Presidential Fellowship, he dedicates several hours every week to working on research.

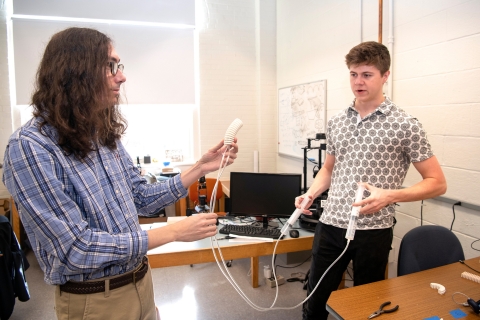

In the fall of 2021, he was matched with Professor William Scott, mechanical engineering, on a soft robotics project. "The idea of robotics has always been something I've enjoyed," Covell says, explaining that soft robotics, in particular, has a lot of potential. Unlike traditional machines, soft robots can operate in rugged terrain and uncertain conditions, making them the ideal tools for bold and risky operations. Perfected, soft robots could explore places humans can't.

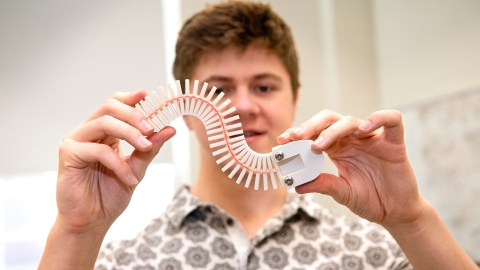

Covell spent most of his first year working in the first-floor lab of the Dana Engineering Building, using a 3D printer to create a robot that can snake through water like an eel. He and his professor chose to work with Filaflex, an elastic material that's as flexible as it is durable.

Mechanical engineering major Caiden Covell '25 (right) is designing a swimming robot under the guidance of Professor William Scott, mechanical engineering. Photo by Emily Paine, Communications

Measuring approximately 12 inches long, the device has a series of 28 rectangular pieces, or "ridges," that are connected to resemble a spine. Pumping water through isolated ridge sections activates an oscillating motion "that's similar to how a fish moves, but it's the whole body — not just the tail," Covell explains. After months of tweaking and testing, they built a prototype that could successfully move without any leaking. The next step for this soft robot? See how it can successfully maneuver an environment.

It's a complex project that's sharpened Covell's technical skills in engineering, especially 3D printing. "I got really comfortable with modeling in the program we use to create all of our designs and print them," he says. He also learned MATLAB coding and used other high-tech tools like micro-controlled pumps, pressure sensors and cameras to record the robot's agility.

The summer between his sophomore and junior years, Covell took his studies overseas through the Bucknell in Dublin study abroad program. For two months, he conducted research within the University College Dublin's mechanical engineering department, using atomic force microscopy, or tiny probing technology, to scan surfaces and create topographical images on a nanometer scale (think cells or molecules). By increasing the speed and strain rate of the probe, Covell and other researchers were hoping to model and analyze the behavior of, say, how a brain would react in a concussion.

Now that Covell is halfway through his Bucknell journey, he has his sights set on tackling as many new experiences as possible before graduating. "I'm really grateful I've been able to do so much here," he says.